#Simcenter 3d

Explore tagged Tumblr posts

Text

Siemens Simcenter 3D: Empowering Simulation Teams with Flexible CAE Licensing

Simcenter 3d: Enjoy Flexible CAE Licensing

Siemens' Simcenter 3D stands out for its commitment to providing flexibility and efficiency to simulation teams. One key aspect contributing to this adaptability is Simcenter 3D's innovative approach to licensing, introducing a value-based token licensing system.

Unlike the traditional model of purchasing individual licenses for each add-on module, Simcenter 3D's token licensing offers a more versatile and cost-effective solution. With this approach, users have the option to acquire packs of tokens, providing instant access to a wide range of Simcenter 3D modules.

The shift to a token-based licensing system brings several advantages to simulation teams:

Cost Efficiency: Token licensing eliminates the need for individual module licenses, allowing teams to optimize costs by acquiring token packs based on their specific needs. This approach provides a cost-effective solution, particularly for teams requiring access to multiple Simcenter 3D modules.

Flexibility and Instant Access: The token system enhances flexibility, enabling teams to allocate resources based on project requirements. This approach is particularly advantageous for dynamic project environments where the demand for specific modules may vary. With token packs, teams can instantly access the required modules without the constraints of traditional licensing models.

Streamlined Collaboration: Simcenter 3D's token licensing promotes collaboration by offering a shared pool of tokens that team members can draw from. This ensures that resources are utilized efficiently across the team, facilitating seamless collaboration on diverse simulation projects.

Scalability: As simulation needs evolve and projects expand, Simcenter 3D's token licensing system provides scalability. Teams can easily scale their simulation capabilities by acquiring additional token packs, aligning with the growth and changing demands of their projects.

Simplified Management: Managing Simcenter 3D licenses becomes more straightforward with token-based licensing. Teams can streamline the allocation and usage of tokens, making it easier to track and manage resources effectively.

To sum up, Simcenter 3D licensing introduces a new level of adaptability and cost efficiency for simulation teams. By moving away from traditional licensing models, Simcenter 3D empowers teams to optimize resources, enhance collaboration, and scale their simulation capabilities seamlessly. In a field where flexibility and efficiency are paramount, Simcenter 3D's approach to licensing reaffirms its commitment to meeting the evolving needs of simulation engineers.

To get a free Siemens Simcenter 3d License trial, reach out to Simulation Experts!

#siemens cae#caesoftware#cae#siemens cae software#simcenter 3d#simulation software#free cae software#siemens simulation software#siemens simcenter 3d software

0 notes

Text

Unleash Innovation with Simcenter: A Deep Dive into Product Performance

In today’s fast-paced engineering landscape, bringing innovative and high-performing products to market quickly is paramount. But how do you ensure your designs meet every performance metric before a single physical prototype is built? The answer lies in the power of advanced simulation. At DDSPLM, we understand these challenges, which is why we champion Siemens Simcenter — a comprehensive and integrated suite of simulation and test solutions that empowers businesses to predict product performance, accelerate innovation, and gain a decisive competitive edge.

What is Simcenter?

Simcenter is much more than just a software tool; it’s a holistic platform designed to tackle the complexities of modern product development. Developed by Siemens Digital Industries Software, Simcenter provides a unified environment for multi-disciplinary simulation, combining 1D system simulation, 3D CAE, and physical testing. This integration allows engineers to virtually assess and optimize product performance across various domains — from structural integrity and thermal behavior to fluid dynamics, acoustics, and electromagnetics.

How Does Simcenter Work?

Simcenter operates on the principle of the digital twin, allowing you to create a virtual representation of your product and simulate its behavior under real-world conditions. Here’s a glimpse into its powerful workflow:

Model Preparation: Simcenter seamlessly integrates with various CAD systems (including Siemens NX), allowing you to import geometries directly. It provides robust tools for geometry editing, de-featuring, and meshing, ensuring high-quality simulation models.

Multi-domain Simulation: This is where Simcenter truly shines. It allows you to simulate a wide range of physics phenomena within a single environment:

Mechanical Simulation: Analyze stress, strain, vibration, durability, and fatigue.

Thermal Analysis: Predict heat transfer, temperature distribution, and thermal management.

Computational Fluid Dynamics (CFD): Simulate fluid flow and its interaction with your design.

Acoustic Simulation: Predict noise and vibration characteristics for quieter products.

Electromagnetics Simulation: Analyze performance for components with permanent magnets or coils.

System Simulation (Simcenter Amesim): Build and analyze 1D models of complex mechatronic systems early in the design process.

Advanced Solving & Optimization: Simcenter employs advanced numerical methods and optimized solvers for efficient handling of complex multiphysics problems. It also offers powerful optimization tools (like those integrated with HEEDS) to explore design alternatives and improve performance.

Post-processing & Visualization: Intuitive visualization tools allow for quick interpretation of simulation results, enabling engineers to make informed decisions faster.

Data Management & Collaboration: Simcenter integrates with Product Lifecycle Management (PLM) systems like Teamcenter, ensuring a seamless digital thread that connects simulation data with design and manufacturing processes, fostering better collaboration across teams.

Key Features of Simcenter

Simcenter boasts an impressive array of features that make it an indispensable tool for engineers:

Comprehensive Multiphysics Capabilities: Structural, thermal, CFD, acoustics, electromagnetics, motion, and more, all within a single, integrated platform.

Seamless CAD Integration: Direct import and associative modeling with various CAD systems, minimizing data loss and ensuring design changes are reflected in the simulation.

Advanced Meshing: Tools for creating high-quality tetrahedral, hexahedral, and polyhedral meshes from complex geometries.

Powerful Solvers: Optimized for speed and accuracy in handling complex simulation scenarios.

Design Space Exploration & Optimization: Automate design iterations and explore a multitude of possibilities to find optimal solutions.

Integrated Testing Solutions: Combine virtual simulation with physical test data for enhanced accuracy and validation.

Scalability: From desktop usage to high-performance computing (HPC) and cloud deployment, Simcenter scales to meet diverse needs.

Open and Extensible Environment: Supports third-party solvers and offers API and scripting capabilities for customization.

How Does Simcenter Benefit Businesses?

The adoption of Simcenter translates into tangible benefits for businesses:

Accelerated Innovation: By front-loading performance prediction, engineers can iterate faster, explore more design options, and bring innovative products to market sooner.

Reduced Development Costs: Minimize the need for expensive physical prototypes and rework by identifying and resolving design flaws virtually.

Improved Product Quality and Reliability: Gain deep insights into product behavior under real-world conditions, leading to more robust and reliable designs.

Enhanced Decision-Making: Data-driven insights from simulations empower engineers to make better design choices earlier in the development cycle.

Increased Efficiency: Streamline simulation workflows, automate repetitive tasks, and foster better collaboration among engineering teams.

Competitive Advantage: Deliver superior products faster and more cost-effectively, outperforming competitors in the market.

Why DDSPLM?

DDSPLM Private Limited is your trusted partner for leveraging the full potential of Simcenter. As an authorized Siemens Expert Partner, DDSPLM boasts over 20 years of experience in providing advanced technical expertise and tailored solutions in India. They offer comprehensive support, including product installation, training, and ongoing technical assistance, ensuring your business maximizes its investment in Simcenter and achieves optimal design outcomes.

Conclusion

Simcenter is more than just simulation software; it’s a strategic asset for any business aiming to thrive in today’s competitive product development landscape. By enabling engineers to virtually explore, analyze, and optimize designs with unparalleled precision, Simcenter empowers innovation, reduces costs, and ultimately delivers superior products to market faster. Partner with DDSPLM to unlock the power of Simcenter and transform your engineering future.

0 notes

Text

How 3D CAD Helps Engineers Perform Thermal Analysis for Spacecraft

The extreme conditions of space pose significant challenges for spacecraft design, particularly in thermal management. Spacecraft experience fluctuating temperatures, intense solar radiation, and the vacuum of space, all of which can impact performance. Thermal analysis is a critical step in spacecraft engineering, ensuring that systems remain operational under these harsh conditions. One of the most transformative tools in this process is 3D CAD (Computer-Aided Design). By integrating CAD with thermal analysis software, engineers can efficiently simulate, analyze, and optimize spacecraft designs.

The Role of Thermal Analysis in Spacecraft Design

Thermal analysis involves predicting how a spacecraft will behave thermally under various conditions. Engineers use simulations to evaluate heat transfer mechanisms such as conduction, convection (if applicable), and radiation. This process ensures that components stay within their operational temperature limits and identifies the need for heaters, radiators, or insulation layers to maintain thermal balance.

Spacecraft thermal analysis typically includes:

Modeling energy exchange factors: Calculating absorbed energy from orbital sources like the Sun and reflected planetary radiation.

Simulating heat dissipation: Predicting how internal components generate and transfer heat during operation.

Designing control systems: Determining heater power requirements and radiator sizing to regulate temperatures.

How 3D CAD Enhances Thermal Analysis

3D CAD tools revolutionize thermal analysis by enabling engineers to create detailed models of spacecraft geometry. These models serve as the foundation for simulations and allow engineers to visualize complex systems under varying environmental conditions. Here’s how 3D CAD contributes to thermal analysis:

1. Accurate Geometry Representation

Spacecraft designs often involve intricate geometries with multiple subsystems. 3D CAD software allows engineers to create highly detailed models that account for every component's size, shape, and orientation. Tools like NX Space Systems Thermal simplify the modeling of large assemblies without requiring manual geometry conversions. This level of detail ensures accurate predictions during simulations.

2. Integration with Thermal Analysis Software

Modern CAD tools are seamlessly integrated with thermal analysis software such as Thermal Desktop or Simcenter 3D Space Systems Thermal. These integrations enable engineers to import CAD models directly into simulation environments without losing fidelity. For example:

Thermal Desktop uses AutoCAD-based models to compute radiative exchange factors and orbital heating via Monte Carlo methods.

Simcenter 3D synchronizes CAD data automatically, reducing errors and improving efficiency during iterative design processes.

3. Material Property Assignment

Thermal performance depends heavily on material properties like conductivity, emissivity, and specific heat capacity. CAD-based tools often include databases of thermophysical properties, allowing engineers to assign realistic materials to spacecraft components. This capability ensures that simulations reflect real-world behavior.

4. Visualization and Post-Processing

Engineers can use CAD-integrated tools to visualize temperature distributions across spacecraft surfaces in 3D. Features like contour plots or scatter plots make it easier to identify hotspots or areas requiring additional thermal control measures. Visualization enhances collaboration among teams by presenting complex data in an intuitive format.

Applications of 3D CAD in Spacecraft Thermal Analysis

Orbital Simulations

Orbital mechanics significantly influence a spacecraft's thermal environment due to changing positions relative to the Sun and Earth. Engineers use 3D CAD models to simulate these dynamics and predict temperature fluctuations over time. For instance, NX Space Systems Thermal enables orbital simulations with synchronized geometry updates for evolving designs

Component-Level Analysis

Thermal analysis extends beyond the spacecraft as a whole—it includes evaluating individual subsystems like electronics or propulsion units. Tools like Solaria Thermal specialize in finite element analysis (FEA) for detailed component-level simulations. Engineers can model copper layers in PCBs or heat dissipation from rocket engines using these tools.

Iterative Design Optimization

Thermal analysis is an iterative process involving multiple design revisions. With CAD-integrated software, engineers can quickly update models based on simulation results without starting from scratch. This agility accelerates development timelines while improving accuracy.

Benefits of Using 3D CAD for Thermal Analysis

The integration of 3D CAD with thermal analysis software offers several advantages:

Efficiency: Automated synchronization between CAD models and simulation tools reduces manual effort.

Accuracy: Detailed geometry and material property assignments result in more reliable predictions.

Cost Savings: Virtual testing minimizes the need for expensive physical prototypes.

Collaboration: Intuitive visualizations enhance communication among engineering teams.

Conclusion

In the realm of spacecraft engineering, thermal analysis is indispensable for ensuring mission success under extreme conditions. The integration of 3D CAD tools with advanced simulation software has streamlined this process, enabling engineers to design more robust systems efficiently. From orbital simulations to component-level evaluations, these tools provide unparalleled accuracy and visualization capabilities.

As space exploration continues to push boundaries, the role of 3D CAD design services in thermal analysis will only grow more critical, empowering engineers to tackle increasingly complex challenges with confidence. Whether designing satellites for Earth's orbit or interplanetary missions, leveraging these technologies ensures that every spacecraft is prepared for its journey into the unknown.

#Thermal Analysis in Spacecraft Design#Spacecraft Design#Thermal Analysis#3D CAD Design#3D CAD Design Services#3d app development services#3d application development#3d mobile app development#3d desktop application development#3d desktop application#3d desktop application development companies#best 3d application development company#3d engineering application development services#3D application development for engineering#3D development tools for engineering applications#3d web application development services#3d mobile application development

0 notes

Text

Siemens Simcenter 3D Low Frequency EM 2020.1 for NX Lifetime

Siemens Simcenter 3D Low Frequency EM 2020.1 for NX Lifetime License. Siemens Simcenter 3D Low Frequency Electromagnetics (EM) 2020.1 for NX is a specialized module within the Simcenter 3D suite that provides powerful simulation tools for analyzing low-frequency electromagnetic fields. This software is essential for engineers and designers working on products and systems where low-frequency…

0 notes

Text

Score big this March with PROLIM's Software Sale! Buy one cutting-edge product, get the second at 50% OFF. Elevate your design process with Solid Edge, NX, Teamcenter, and Simcenter 3D. Every purchase enters you to WIN tickets to a March Madness game! Don't miss out!

To Explore more - http://www.prolim.com/

#ThinkPROLIM#DigitalTransformation#TodayMeetsTomorrow#PLMSolutions#PROLIMMarchMadness#SoftwareSale#TechDeal#DesignInnovation

0 notes

Link

Want to learn how to minimize development time and cost while maximizing performance and reliability, in this fast-changing environment? Discover how the combination of 1D-3D simulation helps engineers achieve more complex, realistic simulations: https://oal.lu/rh2iU For more information mail us at [email protected]

0 notes

Text

Siemens Simcenter Star CCM 2.0.15 2019 Download

Siemens Simcenter Star CCM 2.0.15 2019 Download

Siemens Simcenter Star CCM 2.0.15 Torrent Download 2019 This unique construct supports Technical Data Package requirements by providing ISO standard definitions for 3D and 2D date with no translation requirement if JT data already exists. Siemens Simcenter Star CCM Portable Use the iOS and Android app offerings to visualize 3D JT files using features such as Zoom, Pan, and Rotate. Siemens…

View On WordPress

0 notes

Text

Virtual Sensors Market Size Worth $1.4 Billion By 2025 | CAGR: 27.2% | Global and Regional Forecast | Grand View Research, Inc.

The global virtual sensors market size is expected to reach USD 1.4 billion by 2025, expanding at a CAGR of 27.2%, according to a new report by Grand View Research, Inc. Growing use of virtual sensors in the human activity recognition and in the healthcare domain is driving the market. Implementation of cloud platforms integrated with IoT applications is driving the market growth.

A virtual sensor is expected to achieve multiple objectives built for a specific purpose and result in a meta-analysis about its environment. These circuits can range from very simple to very complex design and undergo changes to produce a desired output. The device is an intangible form of sensor which is activated via two kinds of input, one from user and other from physical sensor. However, virtual sensors, in terms of capabilities are much beyond physical devices that can work individually and collectively irrespective of their physical counterparts.

Trends such as new product launches and agreements are likely to be witnessed in the market. In order to enhance industrial facilities, GE offers virtual sensors to reliantly work on predix, which is a cloud-based platform mainly used in the industrial space. Moreover, Siemens AG is working on digital twin technology for the development of virtual sensing solution for its customers. Siemens AG has developed Simcenter solution that is combining the system simulation and 3D CAE for predicting the performance parameters earlier and throughout the product lifecycle.

The solutions segment is expected to witness largest virtual sensors market share over the forecast period. This is attributed to advent of industry 4.0 and rising demand for cloud-based solutions in the manufacturing facilities. Such solutions are anticipated to promote the robot guidance operations by sensing and reducing accidents.

The market in Asia Pacific offers lucrative growth opportunities in terms of technology output, competitive advantage, and relevancy. In addition, the market witnesses a high influx of investments by stakeholders in various verticals pertaining to product development. Compliance policies and government regulations are pivotal in creating a sustainable market development. North America is expected to hold largest market share over the forecast period. This is attributed to rising demand for IoT cloud models and continuous innovations in the field of VR. In addition, growing adoption of advanced technologies among the companies in the region is driving the market growth.

Browse Full Report (Tables & Figures) @ https://www.grandviewresearch.com/industry-analysis/virtual-sensors-market

Contact Us:

Grand View Research, Inc. 201 Spear Street 1100, San Francisco, CA 94105 United States

Phone:

1-415-349-0058

Toll Free:

1-888-202-9519

Email:

0 notes

Text

Virtual Sensors Market Size Volume, Share, Demand growth, Business Opportunity by 2025

The global virtual sensors market size is expected to reach USD 1.4 billion by 2025, expanding at a CAGR of 27.2%, according to a new report by Grand View Research, Inc. Growing use of virtual sensors in the human activity recognition and in the healthcare domain is driving the market. Implementation of cloud platforms integrated with IoT applications is driving the market growth.

A virtual sensor is expected to achieve multiple objectives built for a specific purpose and result in a meta-analysis about its environment. These circuits can range from very simple to very complex design and undergo changes to produce a desired output. The device is an intangible form of sensor which is activated via two kinds of input, one from user and other from physical sensor. However, virtual sensors, in terms of capabilities are much beyond physical devices that can work individually and collectively irrespective of their physical counterparts.

Trends such as new product launches and agreements are likely to be witnessed in the market. In order to enhance industrial facilities, GE offers virtual sensors to reliantly work on predix, which is a cloud-based platform mainly used in the industrial space. Moreover, Siemens AG is working on digital twin technology for the development of virtual sensing solution for its customers. Siemens AG has developed Simcenter solution that is combining the system simulation and 3D CAE for predicting the performance parameters earlier and throughout the product lifecycle.

The solutions segment is expected to witness largest virtual sensors market share over the forecast period. This is attributed to advent of industry 4.0 and rising demand for cloud-based solutions in the manufacturing facilities. Such solutions are anticipated to promote the robot guidance operations by sensing and reducing accidents.

The market in Asia Pacific offers lucrative growth opportunities in terms of technology output, competitive advantage, and relevancy. In addition, the market witnesses a high influx of investments by stakeholders in various verticals pertaining to product development. Compliance policies and government regulations are pivotal in creating a sustainable market development. North America is expected to hold largest market share over the forecast period. This is attributed to rising demand for IoT cloud models and continuous innovations in the field of VR. In addition, growing adoption of advanced technologies among the companies in the region is driving the market growth.

View detailed insights @ https://bit.ly/3BbqSCM

Virtual Sensors Market Report Highlights

· The service segment is anticipated to witness higher growth owing to growing training and consulting activities for imparting significant knowledge and advantages of virtual sensors

· The cloud deployment segment is expected to witness a steady market growth, which can be attributed to the rise in use of IoT approach

· The aerospace and defense segment is accelerating the product demand for enhancing the passenger’s safety and safer flight operations

· The key players in the virtual sensors market are Siemens AG, General Electric Company; Aspen Technologies, Inc.; Elliptic Laboratories A/S; and Tactile Mobility.

Get Sample PDF Copy @ https://bit.ly/3E9XONY

#Virtual Sensors Market#Virtual Sensors Industry#Virtual Sensors Market Growth#Virtual Sensors Market Analysis#Virtual Sensors Market Forecast#Virtual Sensors Market Size#Virtual Sensors Market Share#Virtual Sensors Market Report#Virtual Sensors Market Research#Virtual Sensors Market Outlook#Virtual Sensors Market Segmentation#Virtual Sensors Market To 2025

0 notes

Text

Computer Aided Engineering (CAE): Siemens Simcenter 3D

In the landscape of Computer-Aided Engineering software solutions in Canada, Siemens stands out as a trailblazer with its Simcenter 3D—a robust and comprehensive suite catering to the diverse needs of CAE experts across the nation.

Canadian CAE experts seek cutting-edge solutions to tackle complex engineering challenges, and Siemens' CAE software portfolio, particularly Simcenter 3D, emerges as a powerful toolset designed to address these demands. Simcenter 3D integrates simulation, testing, and analysis capabilities into a unified platform, offering a holistic approach to engineering simulation.

Siemens' dedication to advancing CAE software in Canada is evident through Simcenter 3D's versatile functionalities. It enables engineers and analysts to simulate various scenarios across multiple disciplines such as structural, thermal, fluid dynamics, and electromagnetics. This breadth of simulation capabilities empowers users to optimize designs, predict performance, and validate product behavior with unparalleled accuracy.

The expertise of Canadian CAE professionals finds a natural fit with Siemens' CAE software, leveraging Simcenter 3D's intuitive interface and powerful simulation tools. From automotive to aerospace, manufacturing to energy sectors, Simcenter 3D's adaptability addresses industry-specific challenges, allowing CAE experts to streamline workflows and drive innovation.

Siemens' commitment to fostering a collaborative ecosystem further enhances the appeal of Simcenter 3D among CAE experts in Canada. The software's seamless integration with other Siemens solutions and third-party applications facilitates data exchange, enabling a unified engineering environment for improved efficiency and informed decision-making.

Moreover, Siemens' CAE software offerings extend beyond mere simulation tools; they embody a vision for the future of engineering. The incorporation of cutting-edge technologies such as artificial intelligence and machine learning into Simcenter 3D showcases Siemens' commitment to staying at the forefront of technological innovation, empowering Canadian CAE experts to explore new frontiers in engineering simulation.

As CAE experts in Canada navigate the complexities of engineering challenges, Siemens' Simcenter 3D remains a beacon of excellence, offering not just a suite of powerful CAE tools but a strategic partnership aimed at driving innovation, optimizing designs, and propelling businesses towards success in the dynamic landscape of engineering simulation. With Siemens CAE software, including Simcenter 3D, Canadian CAE experts find themselves equipped with the tools and support necessary to tackle the most intricate engineering puzzles and transform concepts into reality.

#caesoftware#cae#siemens cae software#CAE Experts in Canada#CAE Experts#Siemens CAE#Simcenter 3d#SImcenter 3d price

0 notes

Text

Unlock Engineering Excellence: Supercharge Your Designs with Siemens NX CAE

In today’s competitive landscape, innovation isn’t just a buzzword — it’s a survival strategy. To bring groundbreaking products to market faster and more efficiently, engineers need tools that can keep pace with their vision. That’s where Siemens NX CAE comes in. At DDSPLM, we’re dedicated to empowering businesses with the best-in-class engineering solutions. Siemens NX CAE, a cornerstone of the Siemens Xcelerator portfolio, is not just software; it’s a gateway to accelerating your product development, optimizing performance, and mitigating risks.

What is Siemens NX CAE?

Siemens NX CAE is a comprehensive suite of advanced simulation tools integrated directly within the NX environment. It empowers engineers to perform a wide range of analyses, predict product behavior, and make informed design decisions early in the development cycle. From structural integrity to thermal performance, and from motion dynamics to multiphysics interactions, NX CAE provides the insights you need to build better products.

Key Features of Siemens NX CAE:

Integrated Environment:

Broad Simulation Capabilities

Advanced Meshing Tools

Powerful Solvers

Results Visualization

Design Optimization

Benefits:

Accelerated Product Development

Improved Product Performance

Reduced Development Costs

Enhanced Innovation

Faster Time to Market

Increased Design Confidence

How Simcenter Simulation and Test Solutions Can Transform Your Business

The power of Simcenter goes beyond individual simulations. It offers a paradigm shift in how you develop and validate products:

Holistic Performance Understanding

Front-loading Performance Engineering

Closed-Loop Product Development

Reduced Physical Prototyping

Optimized Product Reliability

Faster Innovation Cycles

Why Choose DDSPLM for Your Siemens NX CAE and Simcenter Journey?

At DDSPLM, we are more than just a software vendor. We are your trusted partner in digital transformation.

Expertise You Can Rely On

Comprehensive Support

Proven Track Record

Customer-Centric Approach

Holistic Solution Provider

Conclusion

NX CAE, with its powerful Simcenter 3D simulation and test solutions, offers a transformative approach to product development. By enabling comprehensive virtual prototyping and performance prediction, it empowers businesses to innovate faster, optimize designs, and deliver higher-quality products. Partnering with experienced vendors like DDSPLM ensures you have the expertise and support needed to fully harness these advanced capabilities and drive your engineering success.

0 notes

Text

Virtual Sensors Market Projected To Show Considerable Growth By 2025

The global virtual sensors market size is expected to reach USD 1.4 billion by 2025, expanding at a CAGR of 27.2%, according to a new report by Grand View Research, Inc. Growing use of virtual sensors in the human activity recognition and in the healthcare domain is driving the market. Implementation of cloud platforms integrated with IoT applications is driving the market growth.

A virtual sensor is expected to achieve multiple objectives built for a specific purpose and result in a meta-analysis about its environment. These circuits can range from very simple to very complex design and undergo changes to produce a desired output. The device is an intangible form of sensor which is activated via two kinds of input, one from user and other from physical sensor. However, virtual sensors, in terms of capabilities are much beyond physical devices that can work individually and collectively irrespective of their physical counterparts.

Trends such as new product launches and agreements are likely to be witnessed in the market. In order to enhance industrial facilities, GE offers virtual sensors to reliantly work on predix, which is a cloud-based platform mainly used in the industrial space. Moreover, Siemens AG is working on digital twin technology for the development of virtual sensing solution for its customers. Siemens AG has developed Simcenter solution that is combining the system simulation and 3D CAE for predicting the performance parameters earlier and throughout the product lifecycle.

The solutions segment is expected to witness largest virtual sensors market share over the forecast period. This is attributed to advent of industry 4.0 and rising demand for cloud-based solutions in the manufacturing facilities. Such solutions are anticipated to promote the robot guidance operations by sensing and reducing accidents.

The market in Asia Pacific offers lucrative growth opportunities in terms of technology output, competitive advantage, and relevancy. In addition, the market witnesses a high influx of investments by stakeholders in various verticals pertaining to product development. Compliance policies and government regulations are pivotal in creating a sustainable market development. North America is expected to hold largest market share over the forecast period. This is attributed to rising demand for IoT cloud models and continuous innovations in the field of VR. In addition, growing adoption of advanced technologies among the companies in the region is driving the market growth.

To request a sample copy or view summary of this report, click the link below: www.grandviewresearch.com/industry-analysis/virtual-sensors-market

Further key findings from the report suggest:

The service segment is anticipated to witness higher growth owing to growing training and consulting activities for imparting significant knowledge and advantages of virtual sensors

The cloud deployment segment is expected to witness a steady market growth, which can be attributed to the rise in use of IoT approach

The aerospace and defense segment is accelerating the product demand for enhancing the passenger’s safety and safer flight operations

The key players in the virtual sensors market are Siemens AG, General Electric Company; Aspen Technologies, Inc.; Elliptic Laboratories A/S; and Tactile Mobility.

Grand View Research has segmented the global virtual sensors market based on component, deployment, end use, and region:

Virtual Sensors Component Outlook (Revenue, USD Million, 2014 - 2025)

Solution

Service

Virtual Sensors Deployment Outlook (Revenue, USD Million, 2014 - 2025)

Cloud

On-premise

Virtual Sensors End-use Outlook (Revenue, USD Million, 2014 - 2025)

Oil & Gas

Automotive & Transportation

Manufacturing & Utilities

Electronics

Healthcare

Aerospace & Defense

Others

Virtual Sensors Regional Outlook (Revenue, USD Million, 2014 - 2025)

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

U.S.

Canada

Germany

U.K.

China

India

Japan

Brazil

About Grand View Research

Grand View Research, Inc. is a U.S. based market research and consulting company, registered in the State of California and headquartered in San Francisco. The company provides syndicated research reports, customized research reports, and consulting services. To help clients make informed business decisions, we offer market intelligence studies ensuring relevant and fact-based research across a range of industries, from technology to chemicals, materials and healthcare.

0 notes

Text

Siemens Simcenter MAGNET Suite 2021.1 Lifetime License

Siemens Simcenter MAGNET Suite 2021.1 Lifetime License. Siemens Simcenter MAGNET Suite 2021.1 is a comprehensive simulation solution designed for the analysis and design of electromagnetic and electromechanical devices. This suite provides advanced capabilities for 2D and 3D electromagnetic field simulation. Enabling engineers to optimize the performance, efficiency, and reliability of electrical…

0 notes

Link

#NASA - National Aeronautics and Space Administration's Mars Science Laboratory mission, Curiosity, is the largest and most capable rover ever sent to Mars. Read more how NASA Jet Propulsion Laboratory used #Simcenter3D to meet the thermal management challenges: Read more here: https://oal.lu/oD9Nm OR mail us at: [email protected]

#ThinkPROLIM TodayMeetsTomorrow SiemensPartners Simcenter AerospaceEngineering 3D#DigitalTransformation ThinkPROLIM TodayMeetsTomorrow SiemensPartner SmartExpertPartner PROLIMIndia SiemensIndiaPartner PLMSolutions SiemensE

0 notes

Text

Correlating Simulation & Modal Test Results with Simcenter 3D

Quick Overview

youtube

A powerful way of reducing design conservatism is to validate the finite element model used to simulate its performance. Comparing the simulation model’s natural frequencies and mode shapes with those acquired in test generates confidence in the model’s ability to represent the as-built structure. This in turn allows analysts to reduce the safety factors used to compute structural margins of safety. Simcenter 3D FE Model Correlation supports both test and simulation engineers who wish to perform such a comparison, efficiently providing both visual and quantitative feedback.

Background

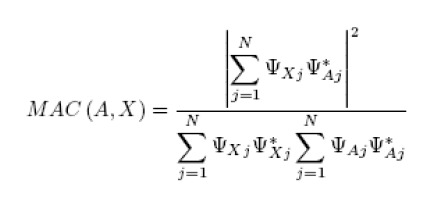

The Modal Assurance Criterion (MAC) is a parameter indicating the degree of consistency between a mode shape from test and another one from simulation. This parameter is a scalar value between 0 and 1: A MAC value near 1 indicates a high degree of correlation or consistency between two mode shapes.

Suppose {ΨA} and {ΨX} are two mode shapes that you want to compare: Their MAC is expressed as follows:

Where:

N is the number of common simulation and test mode shape components

The superscript * indicates the complex conjugate value.

There are LA x LX MAC numbers for given mode shape matrices [ΨA] and [ΨX], where LA is the number of mode shapes in [ΨA] and LX is the number of mode shapes in [ΨX]. These are presented in matrix format:

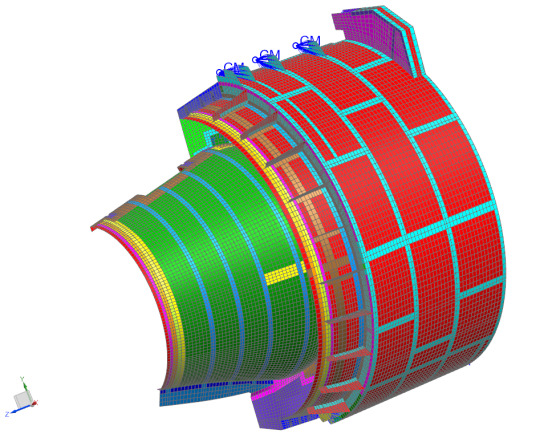

Problem Definition

We wish to compare the natural frequencies and mode shapes of an aircraft engine nacelle finite element model with the equivalent data acquired during a modal test of the actual structure:

The model and test article both represent half the nacelle.

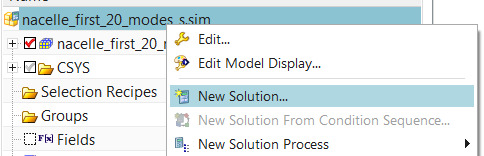

1. Normal Modes Solution

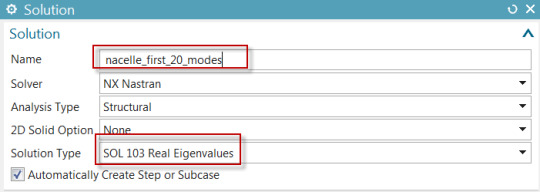

First we create an NX Nastran normal modes solution, requesting the first 20 free-free (unconstrained) modes of the FEM. The first 6 modes describe rigid body motion, in which the structure moves without any internal strain. The next 14 modes are elastic modes, which are the ones we are interested in correlating.

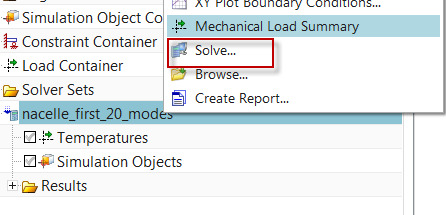

In the simulation navigator, select the top-most sim node and right-click New Solution

The Solution dialog pops up. Enter a Name and as Solution Type, select Sol 103 Real Eigenvalues from the list

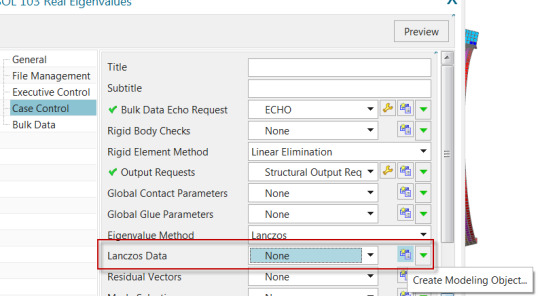

In the Case Control tab of the Solution dialog, next to Lanczos data click Create Modeling Object

In the Real Eigenvalues Lanczos dialog, enter 20 as the Number of Desired Modes. Click OK twice.

In the sim navigator, select the solution, right-click, Solve

After the solution is complete, the mode shapes can be displayed from the post navigator.

2. Import Test Geometry and Results

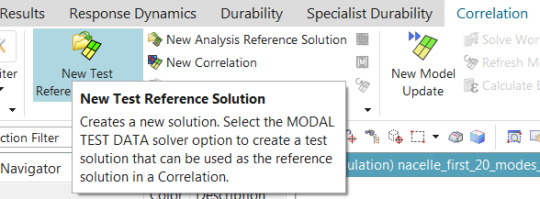

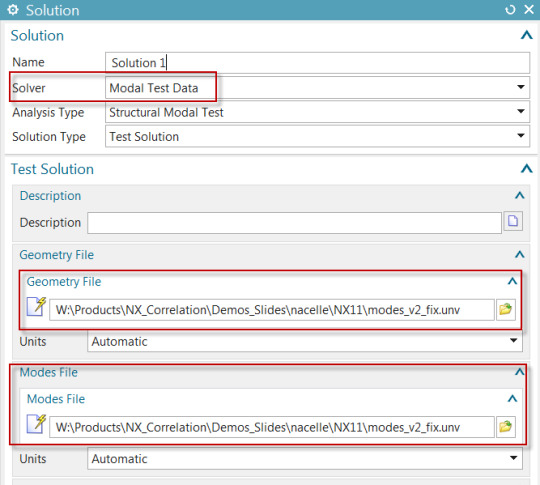

In the Correlation tab of the Simcenter 3D ribbon, click New Test Reference Solution

Set the Solution Type to Modal Test Data, and then select a Geometry File which contains the test geometry (test sensors, coordinate systems and traces) as well as a Modes File containing the test mode shapes and natural frequencies. In this case, the same file contains both the geometry and the mode shapes.

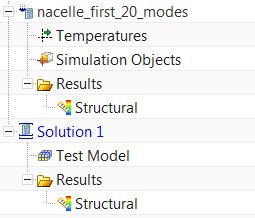

Click OK. There are now 2 solutions in the sim file.

Since Solution 1 is active and points to imported geometry, the fem is now displayed as monotonic grey.

3. Align the Test Model

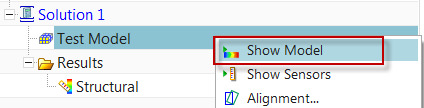

In the sim navigator, under Solution 1, select the Test Model node, and right-click Show Model.

You can also click Show Sensors, to see the individual sensors as triads.

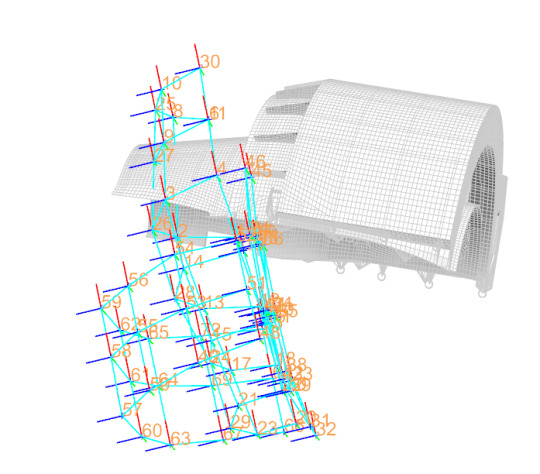

It is clear that the test model and the FEM do not share the same global coordinate system. The test model will have to be aligned with the FEM in order for correlation to be possible.

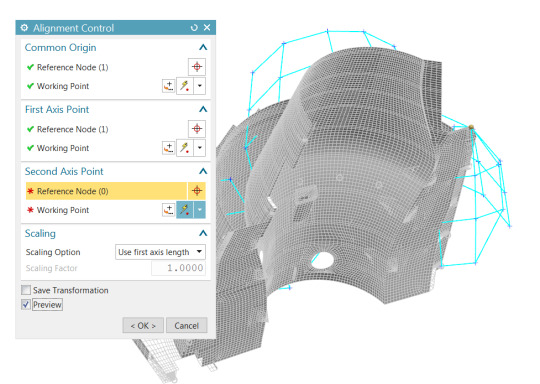

In the sim navigator, under Solution 1, select the Test Model node, and right-click Alignment. The Alignment Control dialog will appear, allowing you to choose 3 test nodes and the equivalent 3 nodes in the FEM. Checking on Preview allows you to see the cumulative effect of the pairs you have selected.

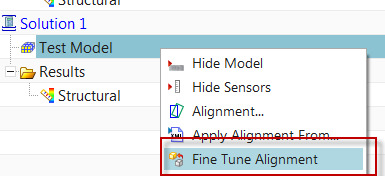

You may need to repeat this step if it is not clear which test sensors correspond to which nodes. After you have successfully performed the alignment, you may select Fine Tune Alignment to further nudge the test model by specifying discrete translations and rotations.

4. Create a Correlation

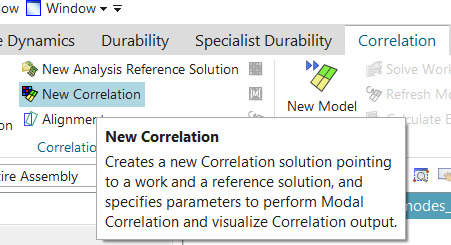

In the Correlation tab of the Simcenter 3D ribbon, click New Correlation

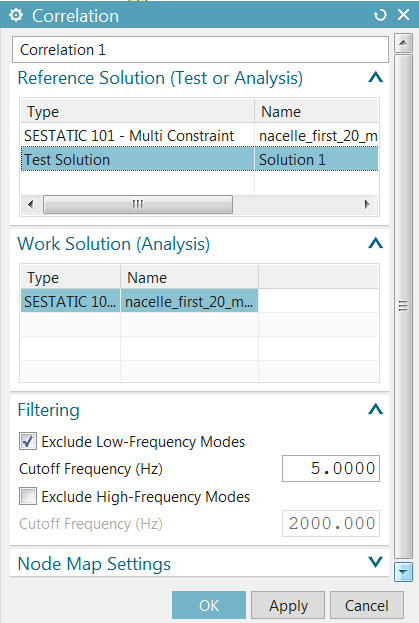

The Correlation dialog appears. Select test Solution 1 as the Reference Solution, and your normal modes solution as the Work Solution

By default, low-frequency (rigid-body) modes are filtered out. In the Node Map Settings group, enter 75 mm as the matching tolerance between the test sensors and the FEM nodes. Click OK.

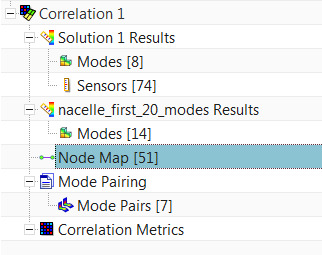

Based on the alignment that was performed, and the tolerance entered in the last step, Simcenter FE Model Correlation was able to map 51 sensors to the FE model nodes, based on proximity. If you repeat the alignment and choose different alignment node pairs, you will see a different number of paired nodes in brackets. The test and analysis mode shapes will be interrogated at these 51 locations to determine the MAC.

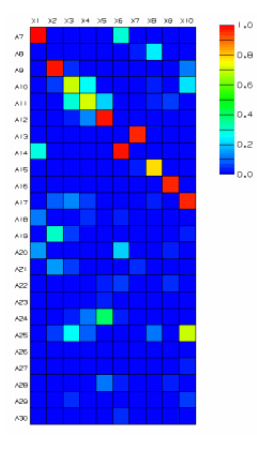

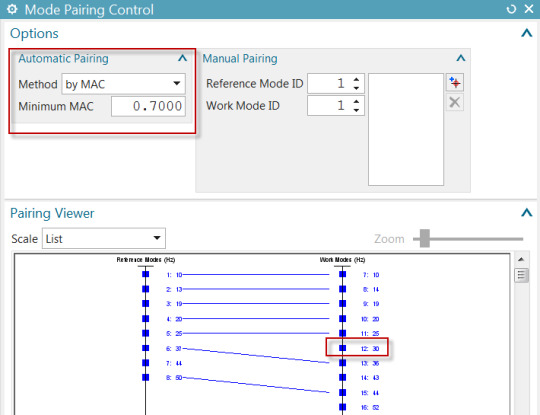

Next, select the Mode Pairing node under Correlation 1, right-click Edit. The default mode pairing criterion is MAC with a minimum value of 0.7: This means that test and analysis modes having the greatest MAC value above 0.7 will be paired, others will not be paired. For example, work (analysis) mode 12 is not paired to any test mode.

Other pairing methods can be selected.

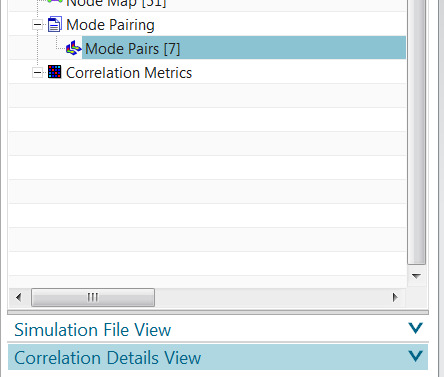

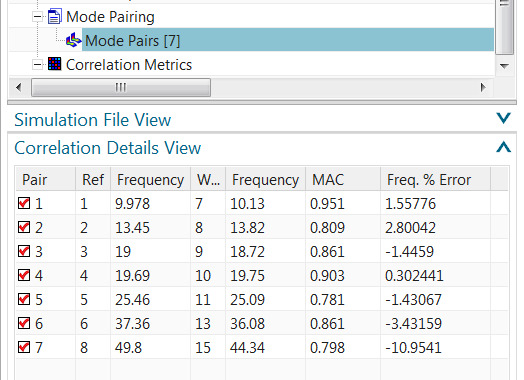

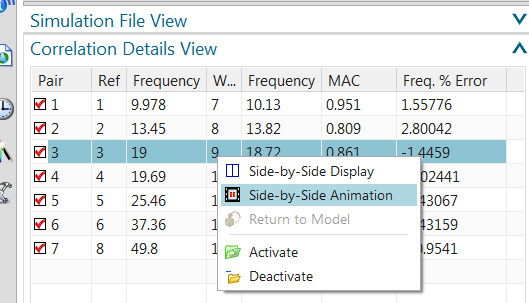

Next, select the Mode Pairs (n) node under the Mode Pairing node and click the Correlation Details View bar

This pops up the Correlation Details View, which shows the test (reference) and analysis (work) frequencies, percent frequency error and MAC, for each mode pair.

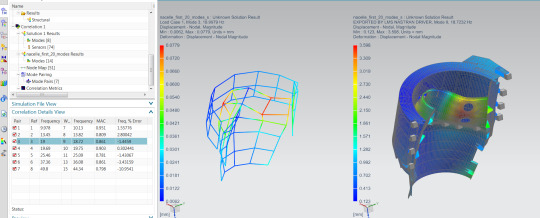

Select any mode pair row in the table, right-click Side-by-Side Animation:

This will bring up a synchronized 2-view layout, showing the test and analysis mode shape animation

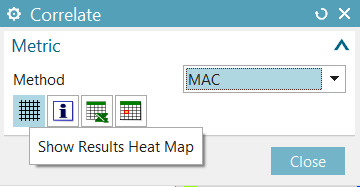

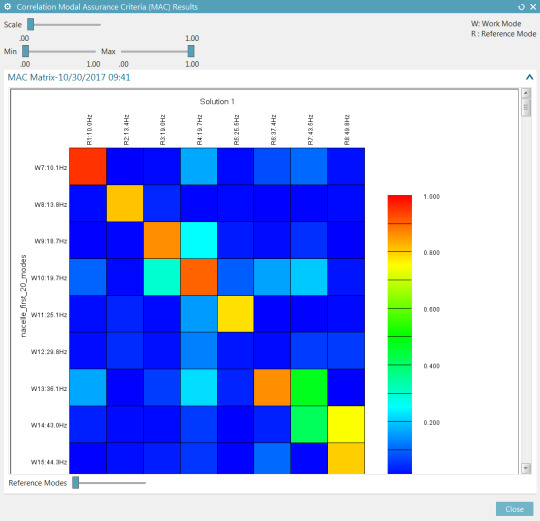

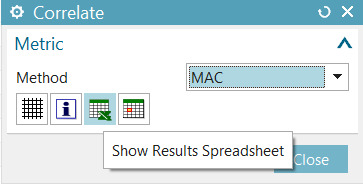

Select the Correlation Metrics node under Correlation 1, right-click Correlate. In the Correlate dialog, click Show Results Heat Map

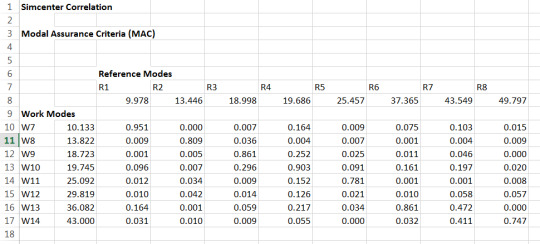

The heat map display shows the MAC matrix

In the Correlate dialog, click Show Results Spreadsheet

SC FE Model Correlation will send the MAC matrix to an Excel spreadsheet.

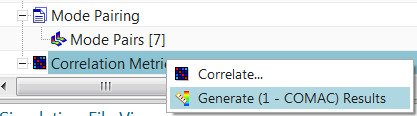

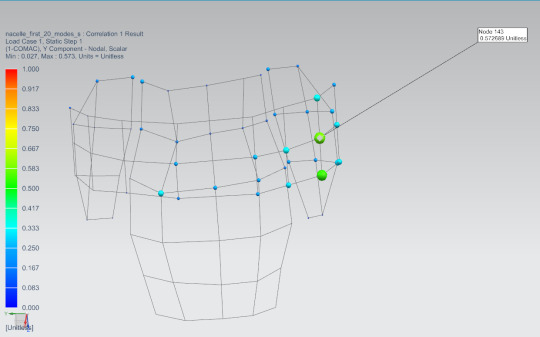

Select the Correlation Metrics node under Correlation 1, right-click Generate 1-COMAC Results.

This will show sensors at which the individual MAC components are poorest.

5 notes

·

View notes

Text

5 Postdoctoral Positions on Modelling, Testing and Inspection of 3D Printed Materials and Composites in Belgium, 2019

The research group “Mechanics of Materials and Structures” at Ghent University is looking for 5 postdoctoral research fellows in the fields of modelling and testing of 3D printed materials and composites. Each vacancy is a full-time position for 3 years.

All vacancies are available in the “Mechanics of Materials and Structures” research group at Ghent University. The offices and laboratories of this group are situated in the south of Ghent (Technologiepark-Zwijnaarde 903, 9052 Zwijnaarde).

The Ghent University is a top 100 university and one of the major universities in Belgium. Our 11 faculties offer a wide range of courses and conduct in-depth research in both exact and social sciences. Ghent University aims to encourage its students to adopt a critical approach within a creative, development-oriented educational and research environment.

Advertisements

Scholarship Description

Applications Deadline: Feb 28, 2019

Course Level: Scholarship is available to study postdoctoral programme.

Study Subject:

Postdoctoral vacancy (3 years) on patient-specific design and finite element modelling of 3D printed medical implants.

Postdoctoral vacancy (3 years) on automated software workflow for medical application of 3D printed technologies.

Postdoctoral vacancy (2.5 years) on multi-axial fatigue modelling and testing for 3D printed metal parts.

Postdoctoral vacancy (3 years) on modelling interfacial debonding of short fibre-reinforced composites.

Postdoctoral or PhD vacancy (3 years) on non-destructive inspection of 3D printed metal parts using ultrasound.

Nationality: Scholarship is available for students of Belgium.

Number of Scholarships: Numbers not given

Scholarship can be taken in Belgium

Eligibility for the Scholarship

Eligible Countries: Scholarship is available for students of Belgium. Entrance Requirements: Applicants must meet the following criteria:

Only candidates with a PhD degree or equivalent experience should apply. The candidate should have a strong background in design and FE modelling for medical applications. He/she will closely work together with the other postdoc in the team (see another vacancy) and is willing to travel frequently to meet and discuss with the other project partners in the neighbouring countries.

Only candidates with a PhD degree or equivalent experience should apply. The candidate should have strong programming skills (Python, C++, C#,…) and has experience with different software tools for patient-specific design of implants, for example: (i) medical image segmentation software (Mimics, SimpleWare, Amira,…), (ii) FE tools (Abaqus, Ansys, Simcenter,…), (iii) topology optimization (Autodesk Within Medical, Altair/Optistruct, Frustum/Generate,…). He/she will closely work together with the other postdoc in the team (see another vacancy) and is willing to travel frequently to meet and discuss with the other project partners in the neighbouring countries.

Only candidates with a PhD degree or equivalent experience should apply. The candidate should have a strong background in fatigue life prediction for metals (e.g. critical plane approaches) and have experimental experience with fatigue testing. Experience in the simulation of AM metals is recommended.

Only candidates with a PhD degree should apply. The candidate should have a relevant background in computational mechanics of materials, preferably combined with experience in Mean Field Homogenization methods or variational methods.

Application Procedure

How to Apply: You write a detailed Curriculum Vitae in Dutch or English, containing:

Your personal details (name, address, date of birth, nationality,…)

Your education, subject of master thesis and degrees

Your work experience (previous jobs)

Additional skills (finite element software, programming languages, communication skills, …)

Mastered languages (Dutch, English, French)

References (previous projects in the domain, published papers,…)

You send the C.V. by post or e-mail to the following person:

Scholarship Link

Advertisements

Post navigation

Need Scholarship Help? Comment and Discuss.

Advertisements

Featured Scholarships

Free Online Courses (MOOC)

Source: https://scholarship-positions.com/postdoctoral-positions-on-modelling-testing-inspection-of-3d-printed-materials-and-composites-belgium/2018/12/26/

0 notes